Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

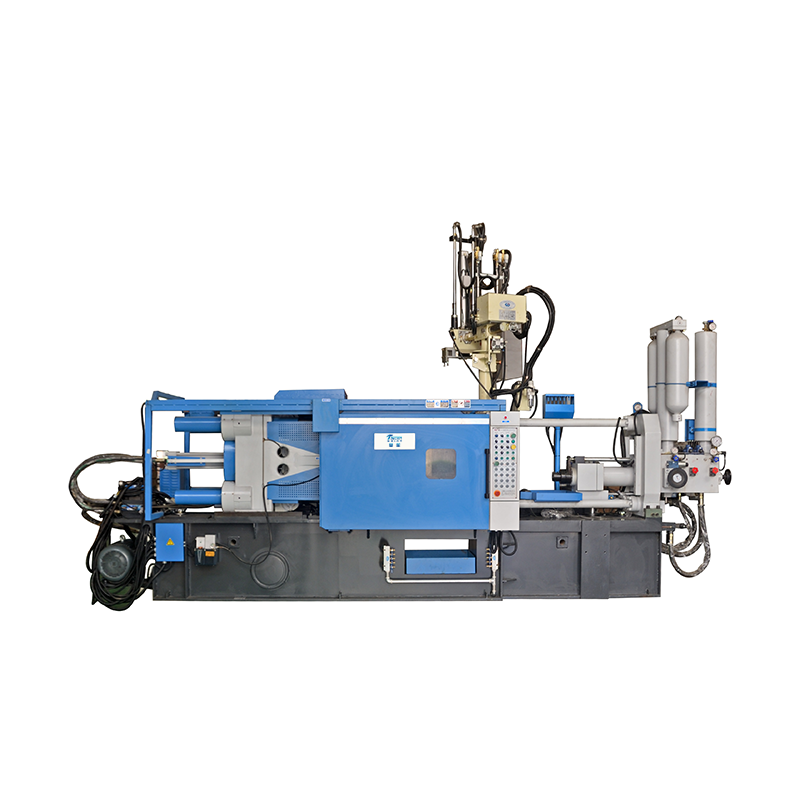

TSUENSAINT Hook Button Metal Badge Die-casting Machine 300kn-2000kn

The TSUENSAINT hot chamber die casting press machine, designed for precision in producing hardware, hooks, buttons, and metal badges. With a clamping force ranging from 300kN to 2000kN, this machine excels in die-casting processes, ensuring high-quality and intricate results. Elevate your manufacturing capabilities with TSUENSAINT's advanced technology for efficient and reliable production.

- Product Details

-

Download

Hot Chamber Die Casting Machine

Product Description

The TSUENSAINT hot chamber die casting press machine sets the industry standard for precision manufacturing of hardware, hooks, buttons, and metal badges. With an adaptable clamping force ranging from 300kN to 2000kN, this machine ensures versatility in die-casting processes, producing intricate and high-quality components. Its advanced technology guarantees efficient and reliable production, making it an indispensable asset for manufacturers seeking top-notch results in the fabrication of metal components. From hardware to badges, trust TSUENSAINT for excellence in die-casting technology.

Product Features

- Versatile Clamping Force: Ranges from 300kN to 2000kN, meeting diverse die-casting needs for hardware, hooks, buttons, and metal badges.

- Precision Die-Casting: Engineered for intricate and high-quality results in fabricating various metal components.

- User-Friendly Design: Intuitive interface and controls for seamless operation in the manufacturing environment.

- Durable Construction: Robustly built to endure continuous die-casting operations, ensuring long-lasting reliability.

Product Advantages

- Consistent Quality: TSUENSAINT's hot chamber die-casting machine ensures a consistent and high-quality finish for components. This reliability meets both aesthetic and functional demands, essential for applications in hardware, hooks, buttons, and metal badge industries.

- Adaptive Production Planning: The machine's capability to handle various clamping forces allows manufacturers to adapt production plans efficiently. This adaptability ensures optimal production planning, catering to specific project requirements with precision.

- Streamlined Workflow: Designed with user-friendliness in mind, the machine's intuitive interface and controls contribute to a streamlined manufacturing workflow. This optimization enhances the overall production process, promoting efficiency and reducing downtime.

- Easy Maintenance: The hot chamber die casting machine's thoughtful design facilitates easy maintenance procedures, minimizing downtime for routine servicing. This feature ensures continuous operational efficiency, contributing to sustained productivity in the manufacturing environment.

In search of a reliable hot chamber die casting machine manufacturer? Look no further! Our commitment to customer satisfaction and top-quality manufacturing sets us apart. Trust us for cutting-edge technology and unparalleled service. Your satisfaction is our priority!

Product Specification

| Specification | H/30D | H/50D | H/90D | |

| Clamping Force | Kn | 300 | 500 | 900 |

| Open stroke | mm | 200 | 230 | 280 |

| Ejector Force | Kn | 35 | 50 | 60 |

| Ejector strokc | mm | 50 | 60 | 60 |

| Die-Thickness(Min-Max) | mm | 120‑320 | 120‑340 | 120‑360 |

| Space Between Tie-Bars | mm | 241x241 | 310x310 | 360x360 |

| Diameter of Bars Φ | mm | 45 | 56 | 65 |

| Injection Position | mm | 0 | 0 | 0 |

| Injection Force | Kn | 35 | 65 | 88 |

| Injection Stroke | mm | 110 | 130 | 150 |

| Disengage Strokc | mm | 200 | 192 | 200 |

| injection Weight (zn) | Kg | 0.6(Zn) | 1.1(Zn) | 1.5(Zn) |

| Injection Plunger Diameter Φ | mm | 45 | 50 | 60 |

| System Working Pressure | Mpa | 16 | 16 | 16 |

| Dry CycleTime | S | ≤4 | ≤5 | ≤5.5 |

| Motor Power | Kw | 7.5 | 11 | 11 |

| Pot Capacity | Kg | 160 | 250 | 380 |

| Fuel Oil Consume | Kg/h | 3.6 | 4.8 | 4.8 |

| Electric Furnace Power | Kw | 20 | 24 | 24 |

| Tank Capacity | L | 250 | 300 | 400 |

| Machine Weight | Kg | 3000 | 3500 | 4600 |

| Overall Dimensions of Machine (L*W*H) | mm | 3400x1640x2100 | 3400x1450x1880 | 4220x1700x2020 |

| Specification | H/130D | H/160D | H/200D | |

| Clamping Force | Kn | 1300 | 1600 | 2000 |

| Open stroke | mm | 350 | 350 | 400 |

| Ejector Force | Kn | 88 | 108 | 108 |

| Ejector strokc | mm | 85 | 85 | 100 |

| Die-Thickness(Min-Max) | mm | 170‑450 | 205‑505 | 250‑550 |

| Space Between Tie-Bars | mm | 409x409 | 459x459 | 510x510 |

| Diameter of Bars Φ | mm | 75 | 80 | 90 |

| Injection Position | mm | 0 | 0 | 0 |

| Injection Force | Kn | 108 | 108 | 130 |

| Injection Stroke | mm | 150 | 150 | 175 |

| Disengage Strokc | mm | 200 | 200 | 200 |

| injection Weight (zn) | Kg | 2.1(Zn) | 2.5(Zn) | 3.3(Zn) |

| Injection Plunger Diameter Φ | mm | 65 | 70 | 75 |

| System Working Pressure | Mpa | 16 | 16 | 16 |

| Dry CycleTime | S | ≤7 | ≤7 | ≤7 |

| Motor Power | Kw | 15 | 15 | 15 |

| Pot Capacity | Kg | 360 | 360 | 720 |

| Fuel Oil Consume | Kg/h | 4.8 | 4.8 | 6.3 |

| Electric Furnace Power | Kw | 30 | 30 | 42 |

| Tank Capacity | L | 400 | 400 | 400 |

| Machine Weight | Kg | 5800 | 6150 | 7900 |

| Overall Dimensions of Machine (L*W*H) | mm | 5200x1630x2350 | 5600x1630x2580 | 5950x1750x2600 |

Download

-

HOT CHAMBER.pdf

Download HOT CHAMBER.pdf